Massage chairs are sophisticated pieces of furniture that combine technology and comfort to provide a therapeutic experience. So how are massage chairs made? This involves delving into their design, material selection, construction, and quality control processes.

Design and Conceptualization

The creation of a massage chair recliner begins with an idea, a vision of what the chair will look like and what features it will offer. Designers and engineers collaborate to conceptualize the chair's design, focusing on comfort, functionality, and aesthetics.

Blueprints and Design Documents

Once the concept is clear, detailed blueprints are drafted. These documents provide extensive details for each component of the chair, including sizes, materials, assembly instructions, and more.

Material Selection

Choosing the right materials is crucial. Components like the frame, upholstery, and control panels are carefully selected for durability and comfort. Steel or aluminum is often used for the frame, synthetic leather or fabric for the upholstery, and plastic for the control panel.

Frame Construction

The frame is the foundation of the massage chair, built to handle the weight and movements. It is constructed using durable materials like steel or aluminum, which are precisely cut, molded, and welded.

Massage Mechanism Creation

The massage mechanism is the heart of the chair, often consisting of motors, gears, and rollers that mimic human hands. This system is designed to perform various massage techniques, combining mechanical and electrical engineering expertise.

Upholstery and Padding

The upholstery enhances the chair's comfort and appearance. It is typically made of leather or synthetic materials and is meticulously cut and sewn to fit the frame perfectly.

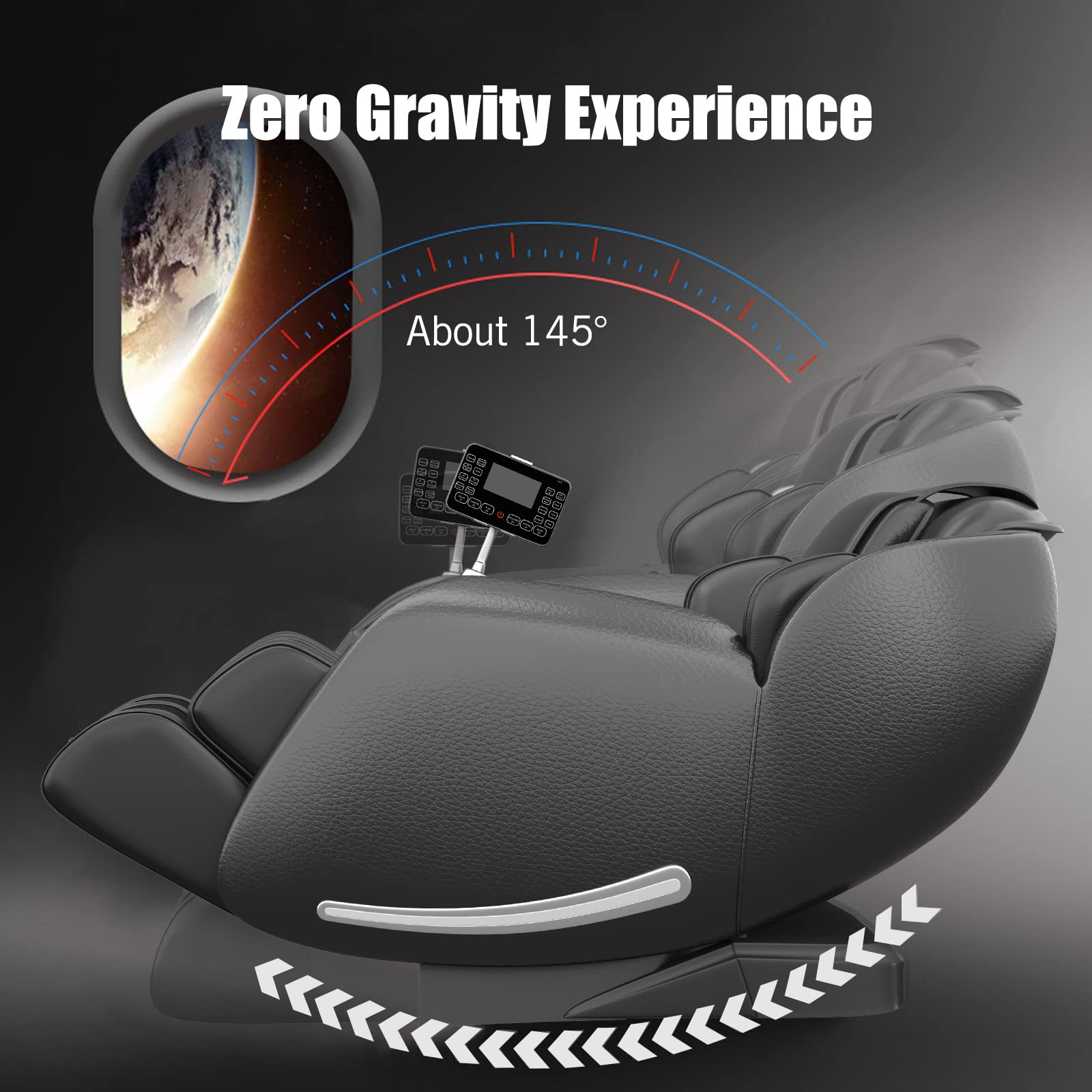

Integration of Modern Technology

Modern massage chairs feature advanced technology such as body scanning, zero gravity, and thermal therapy. Incorporating these features is a significant part of the production process.

Quality Control

After assembly, the chair undergoes rigorous quality assurance checks to ensure it meets standards for functionality, durability, and comfort.

Shipping and Packaging

The final steps involve careful wrapping and shipping of the chair to its new owner, ensuring it arrives in perfect condition after passing quality inspections.

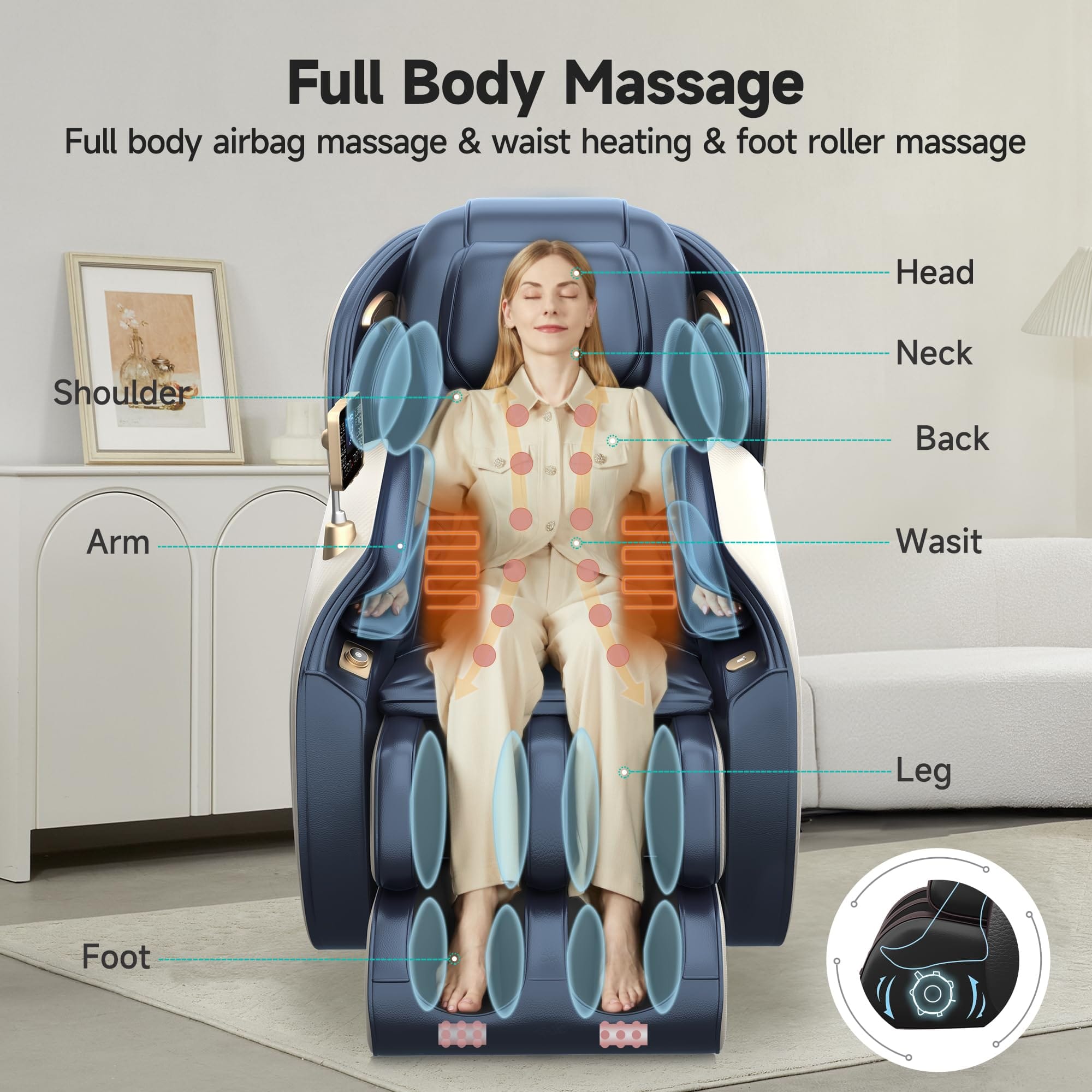

Detailed Anatomy of a Massage Chair

A massage chair's anatomy can be divided into external and internal structures. The external structure includes the frame and chassis, upholstery and padding, and armrests with controls. The internal components consist of motors and actuators, airbags and compression systems, and heating elements.

Frame and Chassis

The frame, often made from steel or reinforced plastic, provides structural integrity and support. The chassis houses the internal components, ensuring they are securely in place and aids in weight distribution.

Upholstery and Padding

High-quality padding ensures comfort during use, and the upholstery material, often synthetic leather or fabric, is chosen for breathability, ease of cleaning, and appearance.

Motors and Actuators

Motors power the massage mechanisms, while actuators control the range and intensity of motion, allowing for customized massage experiences.

Airbags and Compression Systems

Airbags are placed in various areas of the chair to apply pressure and compression, simulating the squeezing motion of a massage therapist. This helps relieve muscle tension and improve circulation.

Heating Elements

Strategically placed heating elements provide therapeutic heat, relaxing muscles and enhancing the massage experience.

PS3100 Massage Chair Brown Refurbished with waist heating

Control Panels and User Interfaces

Intuitive control panels allow users to adjust settings, select programs, and control the intensity of the massage.

Maintenance and Care

Regular cleaning and proper care of the upholstery are essential to maintain the hygiene, appearance, and longevity of the recliner massage chair. This includes surface cleaning, crevice cleaning, and specific care for leather or fabric upholstery.

In conclusion, the production of a massage chair is a complex process that involves careful planning, design, material selection, assembly, and stringent testing. Each chair is a testament to human creativity and the pursuit of comfort and relaxation. Understanding this process can help users appreciate the craftsmanship and technology that go into their massage chairs, making the experience of using one even more rewarding.